Insects and Mites in Farm-Stored Grain

Identification

Insects found in farm-stored grain can include those that feed directly on the grain, referred to as primary pests, and those that feed on grain that is damaged or is going out of condition, referred to as secondary pests. Knowing the identity of insects found in stored grain is critical for determining whether control is needed and what methods would be most economical.

Primary Insect in Stored Grain

Insects that feed directly on the grain include rusty grain beetle, red flour beetle, and sawtoothed grain beetle.

Rusty Grain Beetle (Cryptolestes ferrugineus) is the most common insect that feeds on stored grain in Manitoba. The adult beetles are rectangular, reddish-brown, less than 2 millimetres long (a dime is 1 mm thick), and have long antennae that look bead-shaped when the insect is magnified (Figure 1). Larvae are worm-like, white, and have 2 brown projections on the tail end. Heavy infestations of rusty grain beetles can cause grain to heat and spoil. Rusty grain beetles will have reduced growth in grain with a moisture content of less than 12%.

Be careful not to confuse the rusty grain beetle with the similarly sized fungus feeding foreign grain beetle, which can also be found in stored grain.

Although in many ways the rusty grain beetle and foreign grain beetle may seem similar, there are a few differences that can be used to tell them apart:

- The antennae of foreign grain beetles are club-shaped (Figure 2) and the antennae of rusty grain beetles are shaped like a series of beads but are not clubbed (Figure 1), although you may need to magnify them to see this.

- The foreign grain beetle has a blunt point on the front corners of the thorax (the region behind the head).

- When placed in a glass jar, foreign grain beetles will climb up the sides, while rusty grain beetles cannot.

Figure 1. Rusty grain beetle Figure 2. Foreign grain beetle

The red flour beetle (Tribolium castaneum) is the second most common insect pest of stored grain in Manitoba. Adults are also reddish-brown but are about 4 millimetres long, about twice the length of the rusty grain beetle. Larvae are white with pale brown bands (Figure 3). The red flour beetle cannot feed on undamaged seed, and it will have reduced growth in grain with a moisture content of less than 12%. It prefers grain dust, broken grain and milled stocks.

Figure 3. Red flour beetle

Adult sawtoothed grain beetles (Oryzaephilus surinamensis) are brown, about 3 millimetres long, and when magnified you can see six tooth-like projections on each side of the thorax. Sawtoothed grain beetles are more common in stored oats than in stored wheat and barley. It prefers grain dust, broken grain and milled stock.

Figure 4. Grain of wheat (top left); adults of sawtoothed grain beetle (top right),

red flour beetle (bottom left), and rusty grain beetle (bottom right).

Note how these are much smaller than the grain of wheat.

Secondary Insects and Mites in Stored Grain

Insects and mites that feed on fungus or stored grain that is damaged include the foreign grain beetle, Indian meal moth, psocids and grain mites.

Adult foreign grain beetles (Ahasverus advena) are brown and about 2 millimetres long. Larvae are wormlike, cream-coloured and reach a length of 3 millimetres before pupating. Although foreign grain beetles are considered a fungus feeder, they will feed on grain if the moisture content is in the high end of the acceptable range (eg. 14.5% mc wheat).

Larvae of the Indian meal moth (Plodia interpunctella) feed on all grains and construct tunnels of silk and droppings in the top layer of grain. Only broken kernels of grain and grain dust are attacked as larvae cannot penetrate undamaged grain. They have been found in stored corn in Manitoba.

Psocids are soft-bodied insects, about 1 millimetre long, with long antennae relative to the body size. They are often associated with the presence of moulds. Infestations can develop in grain with a moisture content higher than 14%.

Grain mites are whitish, soft-bodied and about 0.2 to 0.5 millimetres long. They are difficult to see with the naked eye. Several kinds of mites can occur in farm granaries and elevators. Some of these are fungus feeders, while others are predators of mites and insects. Under unfavorable conditions, some grain mites go into a nonfeeding stage which is resistant to drought, heat and even fumigation. They can remain in this stage for months until favourable conditions activate them. Moisture content of the grain influences mite activity. If grain moisture is above 15% mc they can develop, even under relatively cool conditions. The best way to control mites is to dry the grain or turn it from one bin into another.

Canadian Grain Commission Key to Identification of Insects in Stored Grain

The insects covered here are some of the more common insects found in stored grain in Manitoba. Other insects may occasionally be found however. A more comprehensive key to help identify insects found in stored grain in Canada can be found at:

https://www.grainscanada.gc.ca/storage-entrepose/keys-cles/iik-cii-eng.htm

https://www.grainscanada.gc.ca/storage-entrepose/keys-cles/iik-cii-eng.htm

Preventing Insect Problems in Stored Grain

- Clean in and around storage facilities. Grain storage facilities, and the area around storage facilities, should be cleaned thoroughly prior to storing grain.

- Clean equipment used to move grain. Grain left in equipment throughout the summer months can result in new grain being placed into storage becoming infested. Combines, truck beds, grain wagons, augers and other equipment used to move grain should be clean before moving grain. Other potential sources of grain infesting insects include livestock feeds, old seed bags, spilled grain, etc.

- Inspect grain storage facilities for signs of deterioration, especially for leaks or holes through which insects or rodents can gain access to the stored grain.

- Treating storage facilities. Depending on the commodity to be stored, storage facilities may additionally be sprayed or dusted, if needed, with a recommended insecticide before storing grain in the bin (e.g. malathion, diatomaceous earth or cyfluthrin – refer to product labels for details). Note – some commodities, such as canola, flax and sunflowers, should not be stored in facilities recently treated with malathion.

- Dry and Cool Grain. If possible, grain should be dry before being put into storage, and cooled as quickly as possible. For long-term storage, lower the grain temperature below 15°C as soon as possible after the grain is placed in storage. At 15°C the stored grain insects stop laying eggs and development stops. Aeration systems used during the night immediately after harvest should have the grain below 15°C in about 2 weeks. Once the grain mass is cooled to the desired temperature, fans should be sealed to prevent unwanted air migration through the mass that could result in early grain mass warm-up. Cold grain has a longer storage life than warm grain.

Monitoring Insects in Stored Grain

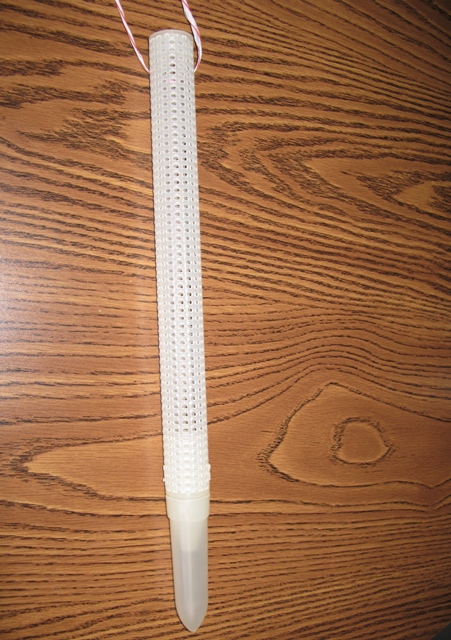

Probe Traps: Insects can be detected in stored grain is by placing probe traps (Figure 5) in the grain and monitoring them. These are tubes perforated with small holes that exclude grain kernels but allow insects to drop into, but not escape from, the trap. Insert so the upper portion of the trap is no more then a few centimeters below the surface of the grain. Traps can be removed by pulling on an attached rope. Remove the traps to inspect for insects every 10 to 14 days until the grain temperature is below 18°C. After this monthly monitoring is sufficient.

Figure 5. Probe trap for monitoring insects.

Bin Probe and Sieves: Stored grain insects can also be monitored by taking grain samples with a bin probe, sieving the grain, and looking in the dockage for insects.

Regular inspection with traps or probe samples will detect populations that may be developing in the bin. Research has shown that probe traps may detect insects earlier than grain samples.

Control of Secondary Insects and Mites

Be sure the grain is in good condition for storage by:

- removing snow if it enters the bin,

- removing crusted areas and hot spots,

- burning or burying discarded grain,

- drying grain, if necessary.

Chemical control of fungus-feeding pests is not necessary, since they cannot survive in sound, dry grain.

Control of Primary Insects

There are 4 main options for controlling insects feeding on stored grain.

Cold Temperatures

An effective method of controlling insect infestations in stored grain in winter is to lower the temperature of the grain. Rusty grain beetles and most other stored grain insects can be killed by periods of low temperatures as follows:

| Grain Temperature in degrees Celsius | Time Required to kill insects |

| -5 C | 12 weeks |

| -10 C | 8 weeks |

| -15 C | 4 weeks |

| -20 C | 1 week |

Grain is a very good insulator. When it is undisturbed, it holds temperature well. Grain in bins over 6 metres in diameter will not cool sufficiently to control some insects without assistance.

You can reduce the temperature of stored grain by:

- Aerating the bin, or

- Turning the grain.

Aeration can reduce the temperature of the grain when the temperature outside of the bin falls below that of the grain bulk (during the early evening, night and early morning). In addition to cooling the grain to stop insect reproduction and development, winter temperatures get cold enough in the Canadian prairie provinces that running aeration fans at these low temperatures can kill insects in stored grain.

Insect populations can sometimes effectively be controlled by turning grain, where it is moved from one bin to another, or removing part of the grain from the bin to a truck or small pile, leaving it to cool, and putting it back in the bin. As outside temperatures decline, moisture migration inside the granary can result in "hot spots" in grain and spoilage by insects and microorganisms. Turning grain breaks up warm, moist, moldy or insect-infested pockets of grain in the bin and spreads it throughout the bulk, and can also reduce the temperature of the grain.

Moving Grain

The use of cyclone-based pneumatic conveyors (grain vacs) to move grain at about 200 bushels per hour has been shown to give good control of insects in stored grain. However, moving too large a volume of grain at a time using a pneumatic conveyor results in the grain protecting the insects and reduced kill of stored grain insects when they hit bends in the conveyor.

Contact Insecticides

Chemical treatment of the bin is another option.

Diatomaceous earth can be used for control of grain feeding insects in many stored grains. It is sold under the trade names Protect-It or Insecto. It damages the cuticle of the insects, reducing their ability to retain moisture. The insects eventually die from dehydration. Optimum conditions to achieve good control with diatomaceous earth include low grain moisture content. When used in empty structures the relative humidity should remain below 55% and the temperature above 15C.

Malathion can be used as an empty-bin treatment to control carry-over infestations or reduce insect entry into the bin. Some formulations can also be applied as a liquid spray or dust as grain flows through an auger or conveyor. It can be used on cereal grains, but stored oilseed crops should not be treated with malathion or stored in bins recently treated with malathion. Grain treated with malathion should not be sold for 7 days, or used for feed until 60 days after application.

Fumigants

Fumigants containing aluminum phosphide, such as Phostoxin, can be applied as pellets into grain and react with moisture in the air to produce the gas phosphine. These fumigants can not be used when the grain temperature is below 5oC as the phosphine is generated too slowly. The use and sale of aluminum phosphide in Manitoba is restricted to licensed pesticide applicators possessing a valid stored agricultural products license. Phosphine gas is extremely toxic to humans.

Refer to the Guide to Field Crop Protection for more details on insecticides that can be used to control insects in stored grain.

Revised: December 2015